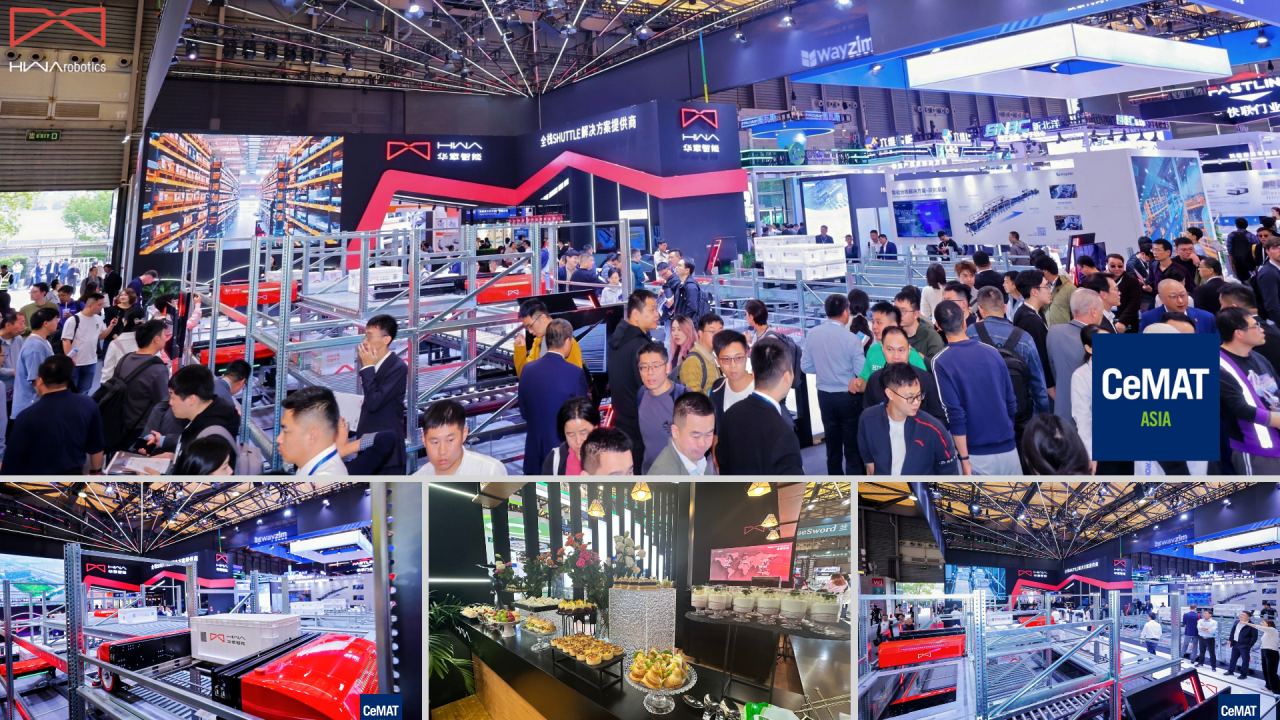

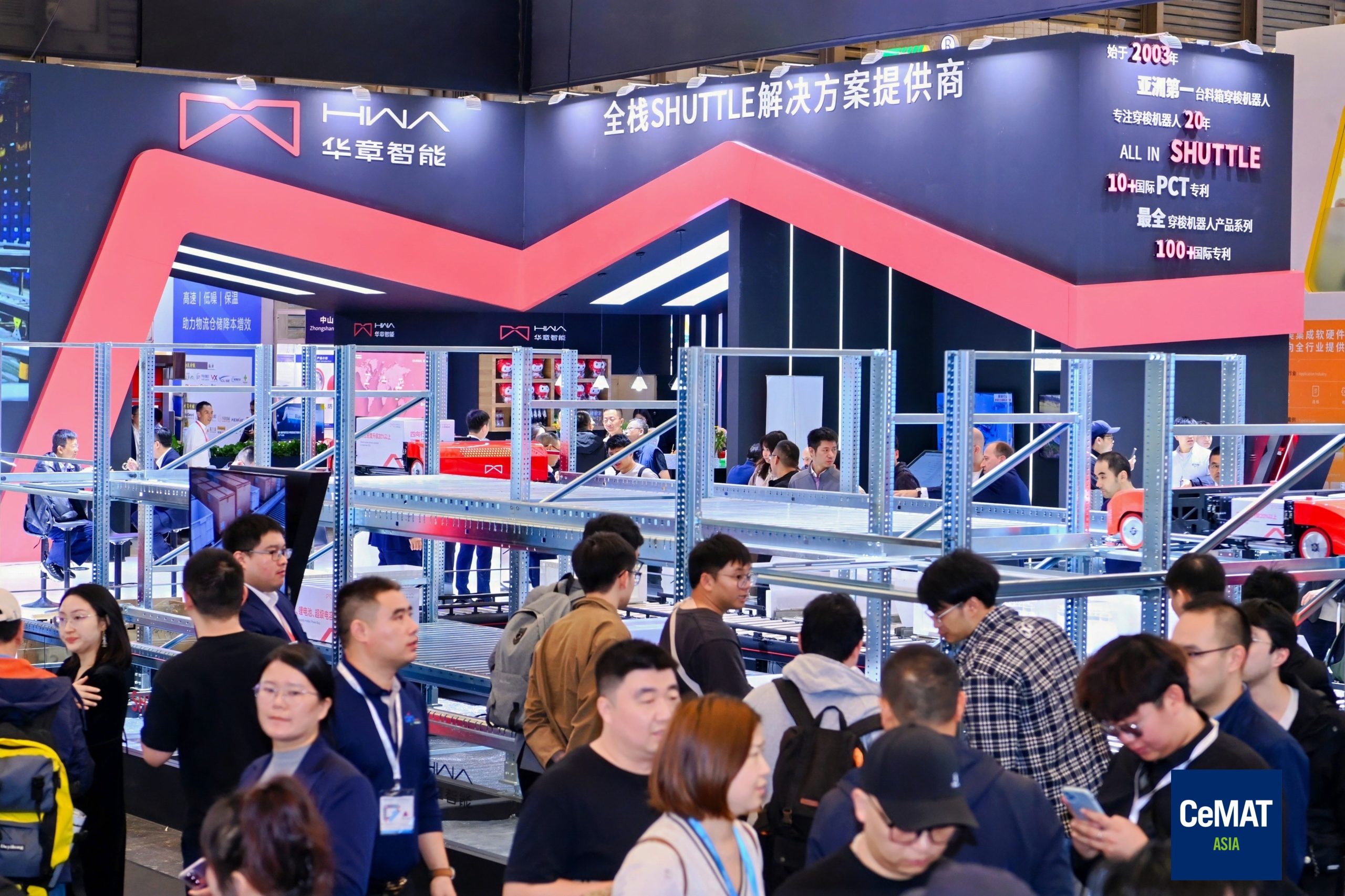

HWArobotics PTE. LTD. is the pioneer and leader in shuttle robot systems

HWArobotics is a warehouse and logistics robot company based in Singapore, dedicated to providing high quality warehouse and logistics robot products for the global market. Our comprehensive product range is featured with pallet shuttle system, tote shuttle system, mini shuttle system, split-case picking system, and associated control software.

Core Products

-

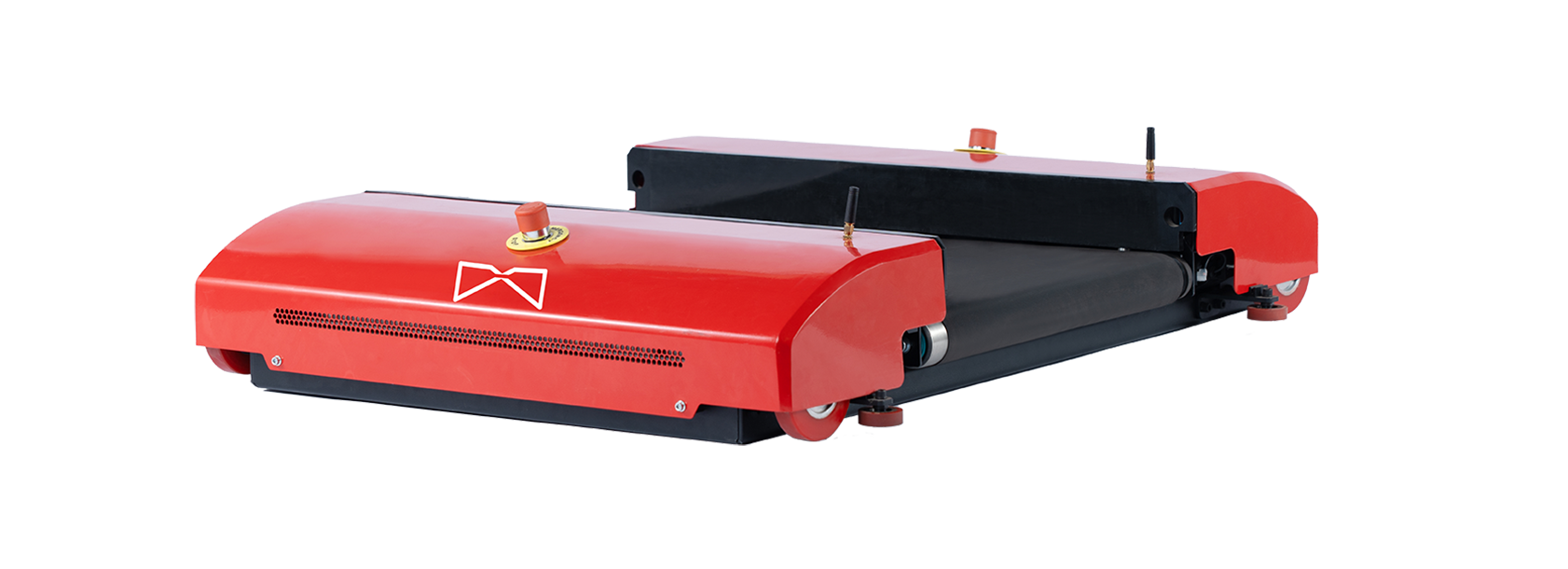

Standard Tote-handling Shuttle Robot Automated Storage & Retrieval System

The SLS300 shuttle robot AS/RS is an efficient buffering solution for totes and cartons, with fixed width load handling device to handle standard size products.

It is also the ideal solution for fully automated crates and cartons with efficient throughput, flexible specification options, better use of space, and more reliable operating equipment.

SLS300

-

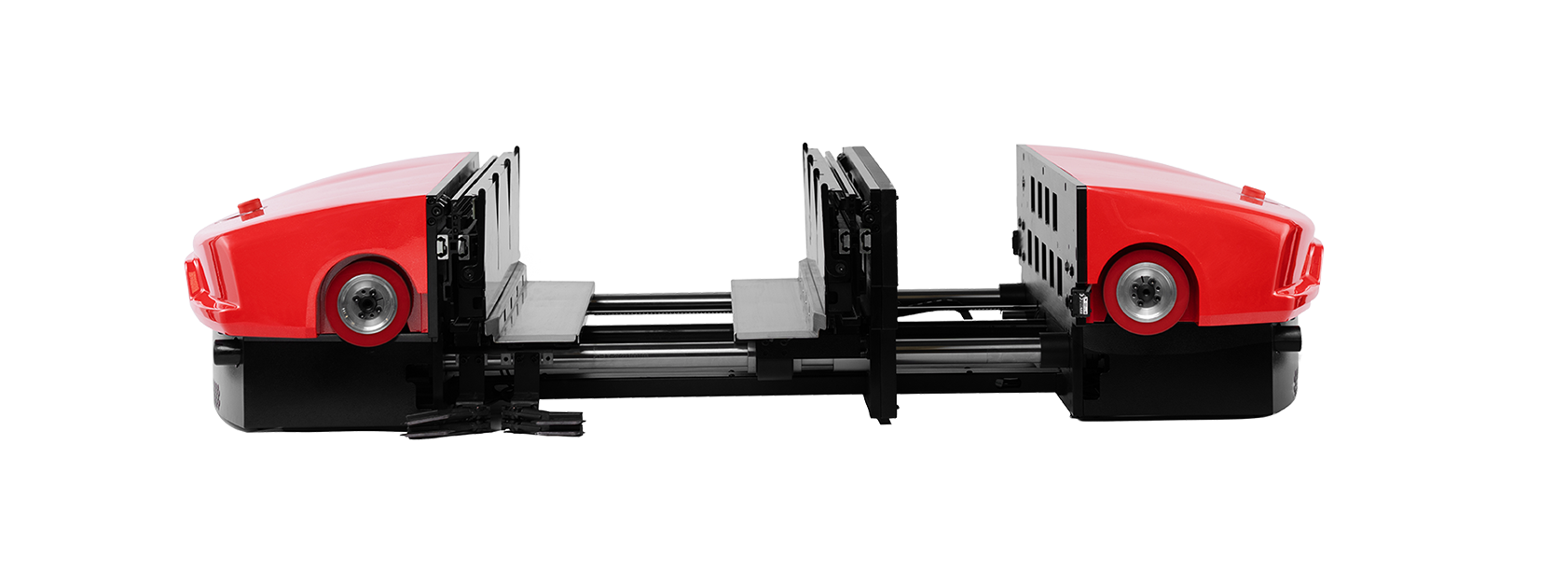

Variable-size Tote-handling Shuttle Robot Automated Storage & Retrieval System

SLS400 is a variable-size tote-handling shuttle robot AS/RS for mixed storage that provides excellent storage density and high rack space utilization, with adjustable width load handling device to handle different product sizes.

SLS400

-

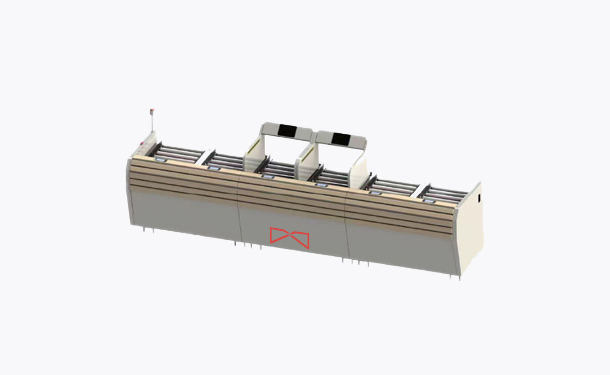

Buffering & Sorting Shuttle Robot Automated Storage & Retrieval System

SLS500 is a shuttle robot system for buffering & sorting based on flow racking and supports warehouses with high throughput, multiple aisles, and large storage depths.

The system also provides a first-in-first-out mechanism, and enables fast automatic replenishment and high storage and retrieval efficiencies.

It is suitable for short-term storage and sorting large numbers of goods.

SLS500

-

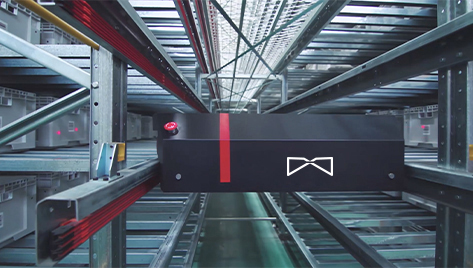

3D Shuttle Robot Automated Storage & Retrieval System

The SLS600 3D shuttle robot AS/RS enables flexible shuttle movements between aisles and system capacity adaptation by adjusting the number of shuttle robots.

SLS600

Featured Solutions

-

Semi-automated solution

HWArobotics' goods-to-person picking system consists of shuttle ASRS, picking station system, conveyor system, and order processing system (OPS). It is by far the most mainstream piece picking solution.

- More