Modern Warehouse Efficiency: AS/RS Warehouse Automation Vs. Warehouse AGVs

Warehouse efficiency is key to success in today’s competitive landscape. Streamlined, efficient operations can maximize the reduction of labour and energy costs. Moreover, higher warehouse efficiency means shorter order processing time, which is beneficial for improving customer satisfaction.

Utilizing warehouse automation technologies has proven an effective strategy to achieve efficiency. The two prominent technologies include AS/RS warehouse automation and Warehouse Automated Guided Vehicles. Read on to learn what they are, their benefits, their differences, and more.

▲Automated Storage and Retrieval Systems (AS/RS) – Overview and Benefits

What is an AS/RS warehouse? Simply put, it refers to a warehouse that utilizes an Automated Storage and Retrieval System, or AS/RS. AS/RS is an inventory management system that relies on computer and robot technology to operate, used for storage, fast order fulfilment, and minimizing errors in inventory management. It is an advanced warehouse automation technology that features a network of computer-controlled systems.

The AS/RS warehouse automation manages the storage and retrieval of goods with great precision and efficiency. Its key components include racking systems, storage and retrieval machines, control systems, warehouse management systems, conveyors, etc. All these components are controlled by sophisticated software.

The key benefits of AS/RS in enhancing warehouse efficiency include:

▷1. Inventory Accuracy

AS/RS ensures accurate tracking and retrieval of inventory, reducing the time and effort required to verify inventory.

▷2. High storage density

AS/RS can reduce space waste through dense storage of items.

▷3. Optimized Labor Allocation

The AS/RS warehouse automation enables workers to focus on value-added tasks by automating repetitive ones.

▷4. Space Flexibility

AS/RS can maximize vertical space by stacking items high and storing the maximum number of items in the smallest area. It’s especially important for limited warehouse space.

▷5. Reduced Downtime

AS/RS ensures continuous workflow and reduces downtime for maintenance and replenishment.

▲Warehouse Automated Guided Vehicles (AGVs) – Overview, Types, and Significance

Warehouse Automated Guided Vehicles (AGVs), which combine automation and mobility, are Autonomous robot vehicles designed to transport goods within a warehouse environment. AGVs have many types, such as forklifts, carts, pallet AGVs, etc. They play a key role in optimizing warehouse efficiency with their ability to enhance the adaptability and flexibility of warehouse operations.

Warehouse AGVs contribute to efficiency by enabling continuous operation, reducing manual transport, and facilitating just-in-time deliveries. These vehicles can navigate tight spaces and work around the clock, reducing congestion and wait times associated with manual labour.

▲Efficiency Comparison: AS/RS Vs. Warehouse AGVs

Both AS/RS and Warehouse AGVs promote warehouse efficiency. While AGVs provide agility and versatility in navigating complex layouts, AS/RS warehouse automation excels in high-density storage and automated retrieval. The following key aspects highlight how both compare in terms of efficiency:

▷1. Throughput Speed

Compared to warehouse AGVs, AS/RS systems offer unmatched speed in storing and retrieving goods within the warehouse. This makes them more suitable for high-throughput environments.

▷2. Space Utilization

TAS/RS systems can optimize space usage by stacking goods vertically. This feature is not achievable with warehouse AGVs because of their physical features.

▷3. Error Reduction

Both technologies minimize errors, but AS/RS warehouse automation is a superior choice due to their precision-guided mechanism.

▷4. Labor Requirements

Warehouse AGVs reduce labour requirements by automating material transport. AS/RS warehouse automation further reduces labour needs by automating storage and retrieval processes.

▷5. Return on Investment (ROI)

Compared to warehouse AGVs, AS/RS warehouse automation typically exhibited a higher ROI because of its rapid order fulfilment and minimized errors, improving customer satisfaction and retention.

▲Product Recommendation: HWArobotics SLS500 Series

HWArobotics is a premier manufacturer of Automated Storage and Retrieval Systems. We were the world’s top three manufacturers to develop the shuttle robot system in 2003. Over the years, we have expanded our warehouse automated solutions category and enjoyed a reputation for innovative and efficient offerings.

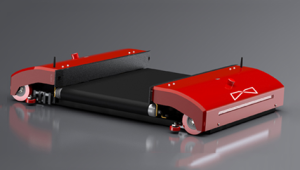

One of our top products in the AS/RS warehouse automation category is the SLS500 Series. It is an advanced AS/RS shuttle robot system designed to enhance warehouse picking and racking efficiency with its many functions. Some of its main features are as follows, but not exclusively limited to:

- High Storage Density: The SLS500 Series optimizes storage space with its effective hybrid storage location design.

- First-in-First-Out Mechanism: With this mechanism, the system ensures efficient inventory rotation and replenishes quickly.

- Multiple Runners and Large and Deep Locations: With these features, the AS/RS warehouse automation system efficiently manages and buffers peak and off-peak replenishment.

- Flexible Layout: The system can be customized to meet specific warehouse requirements.

- Broad Goods Size Compatibility: The SLS500 Series accommodates various inbound buffering of source box sizes and hence, facilitates versatile inventory management.

- Energy Efficient: The SLS500 Series features energy-efficient components to ensure minimal power consumption.

Conclusion

The integration of automation technologies like AS/RS and Warehouse AGVs has transformed the dynamic landscape of warehouse efficiency. While both technologies promote warehouse efficiency, AS/RS warehouse automation is a superior choice, thanks to its many benefits listed above. Our SLS500 Series is a valuable investment for businesses seeking increased warehouse storage and retrieval efficiency.

Choosing a reputed manufacturer of these solutions is crucial to ensure reliable performance and long-term value. HWArobotics is recommended due to its innovative offerings and commitment to enhancing warehouse operations. Contact us to browse more warehouse ranking and support solutions.