Essential Tips for Warehouse Sorter Service and Maintenance

In today’s fast-paced logistics and supply chain management world, warehouse sorters are critical for managing a smooth and efficient material flow. These automated systems can deal with a high volume of items that pass through a warehouse, sorting them based on various criteria such as destination, size, or type.

However, just like other types of machinery, the service and maintenance of warehouse sorters are essential in ensuring they serve the owner for a long time, remain effective, and reduce the cases of downtime. This article intends to walk you through the importance of service and maintenance for warehouse sorting stations and provide essential tips for keeping them in optimal working condition.

(Copyright image from https://www.freepik.com/free-vector/sortation-systems-abstract-concept-vector-illustration-product-sortation-conveyor-based-system-automated-sorting-process-product-identification-logistics-order-processing-abstract-metaphor_11667325.htm#query=sortation&position=2&from_view=search&track=sph&uuid=585611be-e53b-4597-ad8a-2f72dcde7a98″>Image by vectorjuice</a> on Freepik)

Understanding Warehouse Sorters

Sorters are automated sorting machines in warehouses that use advanced technology to sort packages based on predefined criteria. These employ different techniques like conveyor belts, sensors, and mechanical arms to handle a large volume of package assorting effectively.

The primary function of sortation equipment is to automate the sorting process, eliminating the need for manual labor and reducing human errors. They can sort packages from sizes, weight, destination, and even much more specialized parameters. Warehouse sorters provide benefits, including increased efficiency, increased accuracy, decreased labor costs, and orders processed quickly.

They are widely deployed in e-commerce warehouses, distribution centers, and manufacturing factory sectors to help increase speed, accuracy, and throughput, reducing operational costs and labor requirements. Sorters enhance order processing, minimize errors, and improve overall supply chain efficiency, ensuring timely and accurate delivery of goods to customers.

The Importance of Service and Maintenance

The warehouse sorting stations are the essential features of any distribution center. They serve the purpose of making the process of sorting easy, preventing errors, and maximizing productivity. The lack of service or maintenance means such systems can have increased downtime, reduced efficiency, and added costs in repairs and replacements. This is the reason why it is essential for every warehouse manager to have a working schedule so that maintenance and service are done at an interval.

With a regular routine of service and maintenance, warehouse managers would improve their sorting stations’ lifespan by far. Regular inspections enable early intervention and repair. Additionally, proper maintenance helps guarantee that the sorters are in proper working condition to improve their efficiency and productivity. This saves time and money and enhances customer satisfaction by ensuring timely order fulfillment.

Troubleshooting Common Issues

Though warehouse sorting stations are supposed to run smoothly, there might be occasional problems. It is critical to be organized and geared up with troubleshooting techniques to minimize any downtime. Here are some common issues you may face and how to address them:

● Conveyor Jams

Conveyor jams can occur due to misaligned applications, overseas objects, or mechanical issues. Regular inspection and cleansing of the conveyor belts can assist in preventing jams. If a jam does occur, comply with the producer’s instructions to soundly remove the blockage and ensure the smooth waft of packages.

● Sensor Malfunctions

Sensors are crucial in detecting the packages and directing them in the correct direction accurately. However, sensor malfunction may lead to sudden miscalculation during sorting or misdirections of the package. Sensors should be calibrated and maintained routinely to prevent such incidents. If a sensor malfunction occurs, consult the manufacturer’s guidelines for referenece or contact their support team for assistance.

● Sorting Errors

Sometimes, sorting errors may occur due to system glitches or incorrect programming. Regularly reviewing and updating the sorting parameters can help minimize these errors. Additionally, implementing a system to detect and resolve sorting errors in real-time can ensure the accuracy of the sorting process.

● Mechanical Failures

Warehouse sorting stations are often affected by mechanical failures, either from motor failure or the breaking of a certain component. A good schedule that involves changing or greasing an appropriate part helps in the prevention of such an incidence of failure. Spare parts ensure there is no long downtime as a result of an unexpected mechanical failure.

(Copyright image from https://www.freepik.com/free-vector/sortation-systems-abstract-concept-illustration_20769856.htm#query=sortation&position=0&from_view=search&track=sph&uuid=585611be-e53b-4597-ad8a-2f72dcde7a98″>Image by vectorjuice</a> on Freepik)

Best Maintenance Practices for Pre-emptive Intervention

The best performance from your warehouse sorter can be achieved by exercising the best maintenance practices. They encompass:

▲Regular Inspection and Cleaning Routines

Regularly inspect your automatic sorting machine for dusting, wear and tear, and damages. Keep up with a cleaning schedule to prevent clutter of debris and foreign objects that are blocking the machine from functioning properly.

▲Lubrication and Regular Maintenance Schedules

Apply proper lubing to moving parts using the appropriate lubricants to reduce friction and avoid early wear. Look for your particular type of sorter model’s manufacturers’ instructions since different sorts require certain correct lubrication and maintenance schedules.

▲Replacing Worn-Out Parts and Components

Similar to any other machine, the parts and components of a sorting machine might wear out with time. Monitor the lifetime of critical parts and replace them to maintain the best performance at your sorting station.

▲Calibration and Tuning

Calibrate and fine-tune sorting parameters for your warehouse sorter regularly to ensure the right and accurate routing of inventories and sorting of packages. Manufacturers often give their guidelines on how best to calibrate and schedule calibration of the machine for optimum performance.

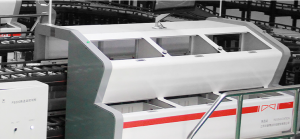

HWArobotics’ Workstations

When it comes to warehouse sorters, HWArobotics gives modern and reliable solutions. Their workstations, including the PSD310 Double-Layer Sorting Station and PSS105 Single-Layer Sorting Station, are designed to satisfy the various desires of modern warehouses.

The PSD310 Double-Layer Sorting Station is a game-changer in split picking for various products, making it perfect for industries like food and e-commerce. It seamlessly integrates with AS/RS and conveyor systems, making it incredibly adaptable. If you’re looking for a more modular approach, the PSS105 Single-Layer Sorting Station is here for you. It brings a semi-automated split-picking solution with a focus on ergonomic design for maximum worker comfort.

With HWArobotics, you not only get innovative solutions but also the support of experts dedicated to helping your operations reach new heights. These workstations are versatile and reliable, ensuring unmatched accuracy in inventory counting and auditing tasks.

Conclusion: Discover HWArobotics’ Distinctive Selling Points

In conclusion, effective service and protection for warehouse sorters are paramount to ensure your sorting stations’ sturdiness, performance, and reduced downtime. By implementing regular inspections, cleansing exercises, lubrication, and changing worn-out components, you can save surprising breakdowns and optimize the overall performance of your warehouse sorters.

Take the next step toward optimizing your warehouse’s sorting methods by exploring HWArobotics answers these days. Visit the HWArobotics website or contact their sales team to discover how their expertise can benefit your warehouse!